Hardware Portfolio

8+ years of experience designing, building, and testing prototype-level mechanatronic systems.

Hardware Resume

Force Feedback Yoke

Building a force feedback yoke poses an interesting challenge. The torque required to provide good feedback is not insignificant. Usually, adding a gearbox to the system is an easy fix; however, increasing the gear ratio is a double-edged sword because the gearbox must be back-driven by the pilot. The more leverage you provide to the motor, the less leverage the pilot has to back-drive it. Our goal is to allow smooth, precise micro-adjustments by the pilot, but any stiction in the motor and gearbox assembly is amplified by the gearbox. I evaluated several gear train options and then carefully designed parts that could be machined to high precision in order to minimize any misalignment that might cause stiction.

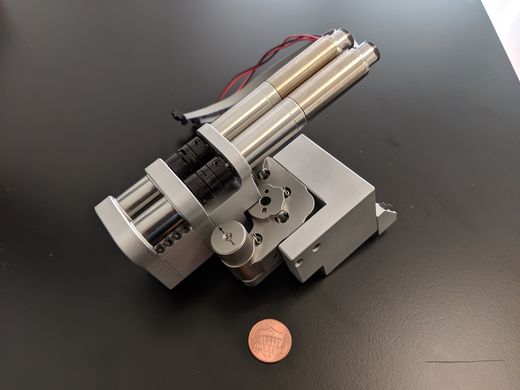

The design is proprietary, so I’ve included a motor housing I designed and built for another prototype.

FLIP

FLIP was my first project as a full-time engineer in 2018. My goal was to build a 3D printer capable of producing parts at record-breaking speeds, measured by volumetric flow rate. This prototype was intentionally scaled down to minimize resin usage and reduce R&D costs. It could produce parts at 4 L/hr but could easily be scaled to exceed 24 L/hr. As far as I’m aware, the latter figure would still be a world record in 2024, though with the important caveat that this technology cannot print extreme overhangs. I acted as the RE for nearly all aspects of this project: I designed all the mechanical parts, machined them, programmed the processes, and ran experiments to test and refine the system. Patent here.

Dental Crown Printer

The dental crown printer was a process I developed by adapting the FLIP process for a specific application. Dental prosthetics can be produced without extreme overhangs and require the use of highly viscous, shear-thinning resins, which made FLIP an ideal starting point. I scaled down the system and tweaked the process so I could minimize the part count, trading speed for compactness and simplicity. I also improved the machine’s precision, as the high opacity of the resin required parts to be produced with layer heights of approximately 15 µm. Patent here.